Cal Nano Services

Cryo-milling / Particle Reduction / Grinding

Cryo-milling, particle reduction, and grinding are techniques commonly used in materials processing to achieve the desired particle size or morphology. Let's delve into each of these methods:

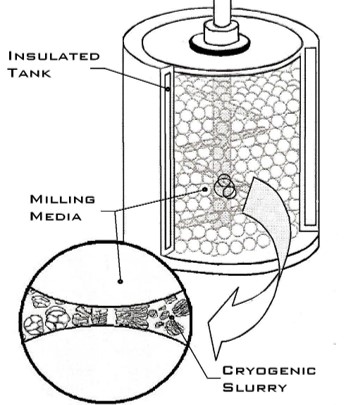

1. Cryo-milling:

Cryo-milling is a technique used to reduce the particle size of materials by milling them at extremely low temperatures, typically below the materials' brittle-to-ductile transition temperature. The process involves milling the material in a cryogenic environment, usually using liquid nitrogen or other cryogenic gases. Cryo-milling is particularly effective for materials that are difficult to grind at ambient temperatures or materials that may be sensitive to heat generation during milling. The low temperature helps to preserve the material's properties and prevents agglomeration, resulting in finer particle sizes and improved homogeneity.

2. Particle reduction:

Particle reduction refers to the process of reducing the size of solid particles. It can be achieved through various methods such as crushing, milling, or grinding. The goal of particle reduction is to obtain particles with a smaller size distribution, which can have significant impacts on the material's properties and performance. Particle reduction techniques are commonly employed in industries such as pharmaceuticals, food processing, and materials manufacturing, where fine or controlled particle sizes are desired.

3. Grinding:

Grinding is a mechanical process that involves the abrasion or attrition of materials to achieve particle size reduction. It typically involves the use of a grinding machine or mill, which applies forces such as compression, impact, or shear to break down the particles. Grinding can be performed using various types of mills, including ball mills, rod mills, and hammer mills, depending on the specific requirements of the material being processed. The choice of grinding technique and equipment depends on factors such as the hardness of the material, desired particle size distribution, and the required throughput.

In the context of CMS (Ceramic Matrix Composites), cryo-milling, particle reduction, and grinding techniques are used to prepare the reinforcement materials (such as ceramic particles or fibers) and achieve the desired particle sizes for optimal dispersion within the matrix material. These processes help to ensure a homogeneous distribution of the reinforcement phase and enhance the mechanical and thermal properties of the composite.

Overall, cryo-milling, particle reduction, and grinding techniques are vital for controlling particle size, improving material properties, and achieving the desired performance characteristics in a wide range of industries, including materials science, pharmaceuticals, and manufacturing.

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software