Sps Fast

THE BEST FOR ACADEMIC / R&D TO HIGH VOLUME FULL PRODUCTION

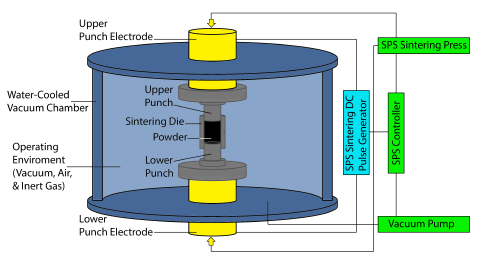

SPS has the advantage of consolidating ceramic, metal and composite materials rapidly as compared to more lengthy conventional processes. Applications include thermoelectrics, aerospace, cutting tools, energy (turbine components, fuel cells), oil & gas, biomedical, and armor applications. SPS can provide fully dense forms (99% plus). The process rapidly consolidates nanomaterials, retaining the fine grain size. SPS is also used to produce functionally graded materials, as well as for bonding dissimilar materials.

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software