Cal Nano Services

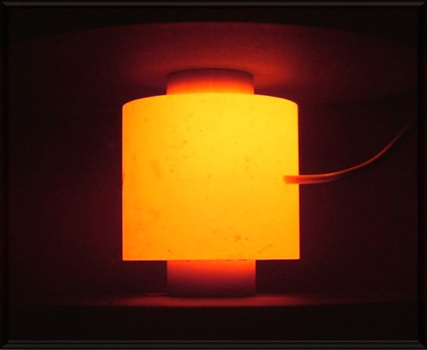

Sintering / Bonding / HIP

Sintering, Bonding, and HIP (Hot Isostatic Pressing) are all techniques commonly used in materials processing and manufacturing. Let's explore each of them in more detail:

1. Sintering:

Sintering is a process that involves compacting and heating powdered materials to form a solid mass. The process typically occurs below the melting point of the materials being sintered. During sintering, the particles are brought into close contact, and the application of heat facilitates diffusion and atomic bonding between particles, resulting in densification and the formation of a solid structure. Sintering is commonly used in the production of ceramics, metals, and composites.

2. Bonding:

Bonding refers to the joining of two or more materials to form a single, unified structure. There are several bonding techniques available, including mechanical fastening, adhesive bonding, and welding. The choice of bonding method depends on the nature of the materials being joined and the specific requirements of the application. Bonding can provide strength, durability, and improved functionality to the assembled components.

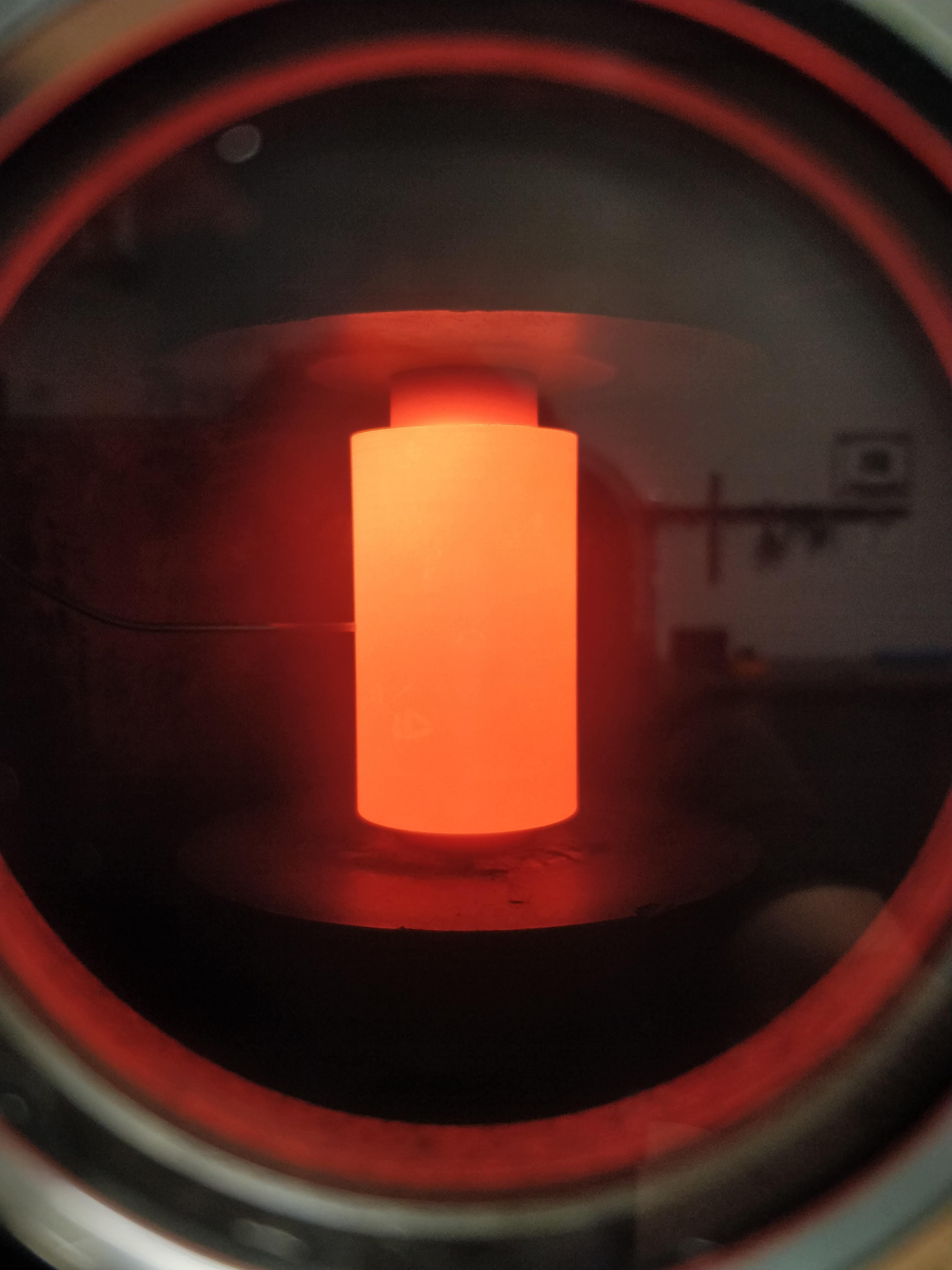

3. HIP (Hot Isostatic Pressing):

HIP, or Hot Isostatic Pressing, is a technique used to improve the mechanical properties and integrity of materials. It involves subjecting a material to high temperature and pressure simultaneously. In the HIP process, a material is enclosed in a pressure vessel and heated to a specific temperature while being pressurized with an inert gas. The combination of high temperature and pressure helps eliminate internal defects, such as pores or voids, and promotes densification and bonding within the material. HIP is often used to enhance the properties of metal and ceramic components, ensuring high strength, uniformity, and improved structural integrity.

In the context of CMS (Ceramic Matrix Composites), these techniques play a vital role in the manufacturing and processing of such materials. Sintering is used to consolidate the ceramic matrix and the reinforcement materials, resulting in a strong composite structure. Bonding techniques, such as adhesive bonding or welding, may be employed to join different components of the CMS together. HIP can be utilized to enhance the properties of the composite by reducing porosity, increasing density, and improving the interfacial bonding between the matrix and the reinforcement.

Overall, sintering, bonding, and HIP are essential processes in the fabrication and optimization of various materials, including CMS, enabling the production of high-performance components with desirable properties.

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software