Sintering / Bonding / HIP

Sintering, Bonding, and HIP (Hot Isostatic Pressing) are all techniques commonly used in materials processing and manufacturing. Let's explore each of them in more detail: 1. Sintering: Sintering is a process that involves compacting and heating powdered materials to form a solid mass. The process typically occurs below the melting point of the materials being sintered. During sintering, the particles are brought into close contact, and the application of heat facilitates diffusion ...

Cryo-milling / Particle Reduction / Grinding

Cryo-milling, particle reduction, and grinding are techniques commonly used in materials processing to achieve the desired particle size or morphology. Let's delve into each of these methods: ...

Material Development / Testing

Material development and testing are essential processes in the field of materials science and engineering. Let's explore each of these aspects in more detail: 1. Material Development: Material development involves the creation and design of new materials or the improvement of existing materials to meet specific requirements. This process typically includes several stages: a. Material Selection: Identifying the desired properties and characteristics required for a particular applic...

Coating Targets/Sputter Targets

Custom Targets up to 450 mm OD! We specialize in producing high-quality custom sputtering targets, tailored to your specific material and performance requirements. Whether you need a small prototype batch for R&D or a larger production run for commercial applications, we offer flexible manufacturing capabilities to deliver consistent, reliable targets in a wide range of compositions, sizes, and purities. Our custom sputtering targets are created using Spark Plasma S...

Nuclear Materials & Reactor Components

DOMESTIC MANUFACTURING OF REACTOR-GRADE MATERIALS Boron Carbide (B₄C), Advanced Ceramics, and Refractory Alloys Manufactured in the United States Using Spark Plasma Sintering (SPS) and Advanced Powder Processing California Nanotechnologies (Cal Nano) supports advanced reactor developers, defense programs, and energy innovators with domestically manufactured nuclear-grade materials and components. We provide U.S.-based manufacturing designed to transition advanced mate...

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

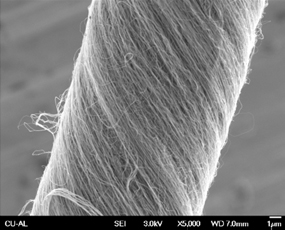

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software